03 Buick Ignition Switch Diagram

1955 Buick Ignition System

SECTION-10-F 1955 BUICK IGNITION SYSTEM

10-39 1955 BUICK IGNITION SYSTEM DESCRIPTION AND OPERATION

1955 Buick Ignition System Components

The 1955 Buick ignition system consists of the 1955 Buick ignition switch, 1955 Buick ignition coil resistance unit, 1955 Buick ignition coil, 1955 Buick ignition distributor, 1955 Buick spark plugs, and the low and high tension wiring. Electrical energy is obtained from the battery while cranking and during idle speeds, and from the generator at higher speeds. These supply circuits must be considered part of the ignition system.

- 1955 Buick Ignition Switch. The 1955 Buick ignition switch has three positions; "LOCK", "ON", and "OFF". When in the "LOCK" position with key removed, the ignition is turned off and the switch is locked. When in the "ON" position the ignition is turned on, and in the "OFF" position the ignition is turned off, with or without the key in place in either position.

The 1955 Buick ignition switch has three terminals which are protected against unauthorized bridging by a metal shield attached to the steering column support. For connections to the 1955 Buick ignition switch terminals refer to the chassis wiring circuit diagram in Section 10-J. - 1955 Buick Ignition Coil Resistance Unit. The resistance unit (resistor) is mounted on the cowl near the 1955 Buick ignition coil and is connected in series between the ignition switch and the positive (+) terminal of the coil. The resistance unit limits to a safe maximum the primary current flow through the coil and the distributor contact points, thereby protecting the contact points during slow Speed operation when they are closed for longer intervals. It also protects against excessive build up of primary current when the ignition switch is closed with engine stopped and contact points closed.

A separate contact in the cranking motor solenoid switch is connected directly to the positive (+) terminal of the ignition coil so that the resistor is bypassed during cranking operation. Elimination of the resistor overcomes the effects of reduced voltage due to the cranking motor drain on the battery. - 1955 Buick Ignition Coil. The oil filled ignition coil is mounted on the rear end of the intake manifold, adjacent to the 1955 Buick ignition distributor. The positive (+) terminal is connected to the ignition switch through the resistance unit, and is also connected to the contact in the solenoid switch which bypasses the resistance unit during cranking of engine. The negative (-) terminal is connected to the primary terminal of the distributor. The secondary (high tension) terminal is connected by a short cable to the center terminal in distributor cap. See figure 10-41.

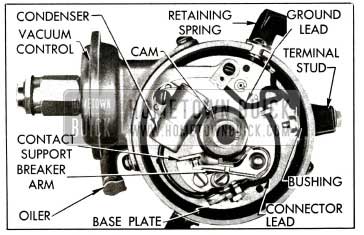

- 1955 Buick Ignition Distributor. The 1955 Buick ignition distributor is mounted on top of the engine crankcase at the rear end. See figure 10-41. It is driven clockwise directly from the camshaft through steel gears which are automatically lubricated by the engine oiling system. The gear thrust is upward against a special bronze thrust washer.

The distributor is of the single contact type with an 8-lobe cam. High speed operation is obtained by an especially light contact breaker arm and a high speed cam. Maximum operating efficiency of the engine is obtained under all speed and load conditions by the centrifugal advance mechanism and the vacuum advance mechanism built into the distributor. - Spark Plugs. AC Type 44-5 spark plugs having 14 MM threads, short (3/8″) terminals, and gaps of .030″-.035″ are specified for all engines. Rubber boots cover the cable terminals at the spark plugs.

- Radio Suppressor and Capacitor. A 10,000 ohm resistor is built into the distributor rotor so that it is unnecessary to install a suppressor on the high tension cable when a radio is installed. A capacitor is mounted on the side of 1955 Buick ignition coil and connected to the positive (battery) terminal of coil when a radio is installed. See figure 10-41.

An additional capacitor must never be connected to the distributor terminal as this will cause excessive pitting of breaker points or engine missing.

1955 Buick Ignition Operating Circuits

To clarify operating principles as well as to simplify the process of tracing troubles, the parts of the 1955 Buick ignition system should be understood to provide two separate and distinct circuits, as follows:

- The Primary Circuit carries the low voltage current supplied by the battery or generator. In addition to these sources of electrical energy, the primary circuit contains the 1955 Buick ignition switch, ignition coil resistance unit, primary winding of the ignition coil, distributor contact points, condenser, and all connecting low tension wiring.

- The Secondary Circuit carries the high voltage surges produced by the 1955 Buick ignition coil, which result in high voltage spark between the electrodes of the spark plugs in engine cylinders. This circuit contains the secondary winding of the ignition coil, coil to distributor high tension lead, distributor rotor and cap, ignition cables, and spark plugs.

Cycle of Operation

When the 1955 Buick ignition switch is turned on and the distributor contact points are closed, battery or generator current flows through the primary winding of the coil and through the contact points to ground. This flow of current through the primary winding of the coil produces a magnetic field around the coil windings and thereby stores electrical energy in the coil.

When the contact points are separated by the revolving distributor cam, the primary circuit is broken. The condenser absorbs the current which tends to surge across the gap as the points separate, thereby producing a sharp break in the flow of current. If the flow of current were not sharply broken it would form an arc which would burn the points badly and would also drain away most of the energy stored in the coil. There would be insufficient energy left in the coil to produce the necessary high voltage surge in the secondary circuit.

The very rapid change in strength of the magnetic field when the primary circuit is sharply broken causes a high voltage to be induced in every turn of both the primary and secondary windings.

The high voltage surge produced in the secondary winding of the coil travels through the cable to the center of distributor cap, through the rotor to the adjacent distributor cap segment from which it is conducted to the proper spark plug by the 1955 Buick ignition cable. The high voltage surge jumps the gap between the insulated center electrode and the grounded side electrode of the spark plug, thus producing the spark required to ignite the charge in the selected combustion chamber of the engine.

As the spark appears at the spark plug gap the energy in the coil begins to drain from the coil through the secondary circuit, thus sustaining the spark for a small fraction of a second. During this interval the condenser discharges back through the primary circuit, producing an oscillation of the current flow in the primary circuit during the brief instant that is required for the primary circuit to return to a state of equilibrium. Note particularly that the 1955 Buick ignition condenser does not discharge until after the spark has occurred at the spark plug gap.

The sequence of action described above is repeated as each lobe of the distributor cam moves under and past the rubbing block on the contact breaker arm to cause the contact points to close and open.

Control of 1955 Buick Spark Timing

The timing of the spark with respect to piston position in the cylinder must vary in accordance with operating conditions if best engine performance is obtained. The 1955 Buick spark advance for obtaining satisfactory idling should be as low as possible. At high speed, the spark must occur earlier in the compression stroke in order to give the fuel-air mixture ample time to ignite, burn and deliver its power to the piston as it starts down on the power stroke.

Under part throttle light load operation, a smaller amount of fuel-air mixture (by weight) enters the cylinder so that the mixture is less highly compressed. Under this condition, advancing the spark permits fuller utilization of the fuel-air charge. During acceleration or on heavy loads (wide open throttle) the spark advance required to develop the maximum power of the engine is considerably less than that required for light loads.

Control of 1955 Buick spark timing to satisfy these constantly changing operating requirements is obtained in three ways, as follows:

- Initial, manual setting of distributor is made so that contact points open at a specified position of piston, as indicated by a timing mark on crankshaft pulley or balancer. See 1955 Buick Ignition Timing (par. 10-41).

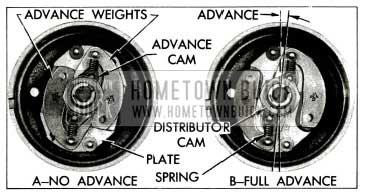

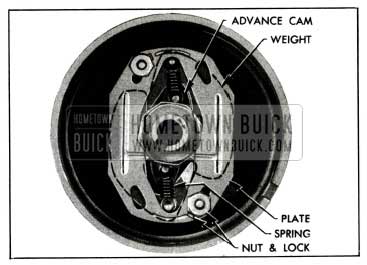

- Centrifugal advance is governed by speed of engine. The centrifugal advance mechanism built into the distributor consists of an advance cam which is integral with the distributor cam, a pair of advance weights, two springs, and a weight base plate which is integral with the distributor shaft.

At low Speeds the springs hold the advance weights as shown in figure 10-42, view A, so that there is no additional spark advance and the spark occurs in accordance with the initial manual setting of distributor. As speed increases, centrifugal force causes the advance weights to throw outward and push the advance cam, thus rotating the distributor cam ahead of the distributor shaft. This causes the distributor cam lobes to open and close the contact points earlier in the compression stroke so that the spark is advanced. See figure 10-42, view B.

1955 Buick Centrifugal Advance Mechanism

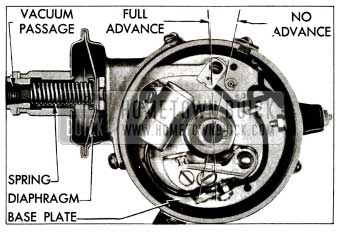

- 1955 Buick Vacuum Controlled Advance is governed by manifold vacuum during part throttle operation. The contact points are mounted on a base plate which is supported by three nylon buttons or bearings upon a stationary support plate in distributor housing. The base plate is held to the support plate by a retainer washer seated in a groove of base plate hub, which serves as a bearing to permit the base plate to rotate on the support plate. The base plate and attached contact points can be rotated around the distributor cam by the link of the vacuum control mounted on the side of distributor housing. See figure 10-43.

1955 Buick Vacuum Advance Mechanism

The 1955 Buick vacuum control contains a spring loaded diaphragm. The spring-loaded side of the diaphragm is connected by a pipe to an opening in the carburetor barrel. This opening is on the atmospheric side of the throttle valve when the throttle is in idling position so that there will be no vacuum to operate the advance mechanism.

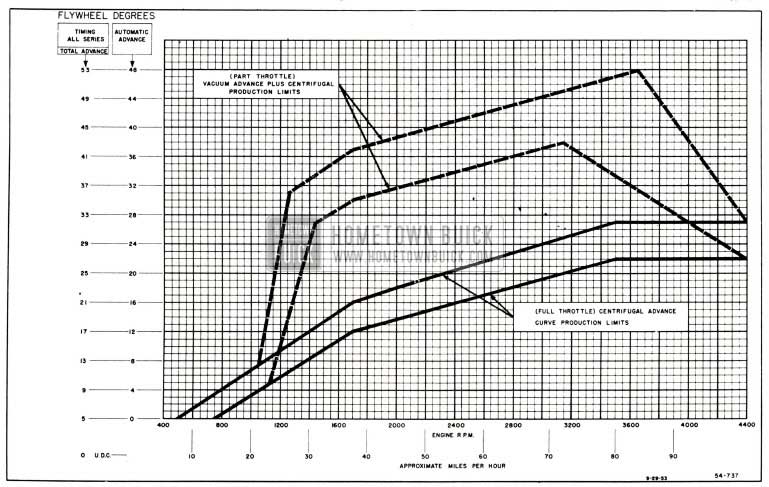

When the 1955 Buick throttle valve is opened equivalent to approximately 18 MPH, the vacuum at the opening is sufficient to act on the control diaphragm, causing it to compress the spring and to rotate the breaker plate in a clockwise direction. This moves the contact points so that the distributor cam lobes open the points earlier in the compression stroke. The amount of throttle opening determines, in part, the amount of intake manifold vacuum and thus the amount of – spark advance obtained. The advance obtained by the vacuum control is added to the advance obtained by the centrifugal advance mechanism, shown in figure 10-44.

1955 Buick Distributor Spark Advance Chart

10-40 INSPECTION, CLEANING, ADJUSTMENT OF 1955 BUICK IGNITION SYSTEM

The best assurance of obtaining maximum service with minimum trouble from the 1955 Buick ignition system is to follow a regular inspection procedure at periodic intervals and to correct any sub-normal conditions disclosed by the inspection. Lubrication of the distributor is covered under Periodic Lubricare Instructions (par. 1-1 and 1-2). The following inspection procedure will disclose any sub-normal condition in 1955 Buick ignition system that requires correction.

Battery and Primary Circuit Wiring

- Check battery and cables to make sure 1955 Buick ignition system has a dependable source of energy (par. 10-15).

- Check primary circuit wiring connections at battery junction block, charge indicator, 1955 Buick ignition switch, ignition coil resistor, ignition coil, and distributor. Also, check the resistor by-pass connections at cranking motor solenoid switch and battery junction block.

- If any connections are loose, disconnect and clean terminals thoroughly, then connect and tighten securely. Check wiring insulation and repair any breaks with tape.

Centrifugal and Vacuum Advance Mechanisms

- Remove 1955 Buick distributor cap. Turn the rotor in a clockwise direction until advance weights are fully extended, release rotor and allow springs to return weights to retard position. Repeat several times. If springs do not return weights to stop without sticking, or there is excessive free movement of rotor and cam in the retard position, remove distributor for correction.

- Rotate 1955 Buick breaker plate by pushing against condenser and note whether spring in vacuum control unit returns breaker plate to full retard position.

Contact Points, Condenser, and Connections

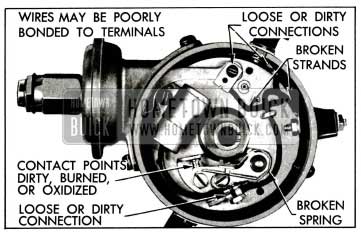

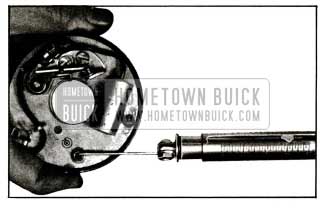

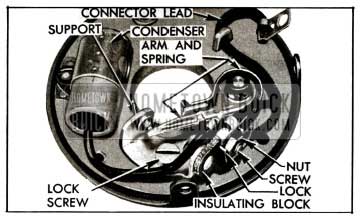

- Check contact point and condenser connector leads and breaker plate ground lead for loose or broken connections. Inspect for broken breaker arm spring and loose or broken rubbing block. See figure 10-45.

1955 Buick Points of Resistance in Primary Circuit of Distributor

- 1955 Buick Ignition coil resistance unit not properly connected into circuit between ignition switch and coil positive (+) terminal.

- Burned points may be caused by a defective condenser. Test the condenser (par. 10-44).

- Burned points may be caused by insufficient contact point opening. This item will be checked later.

- Oil vapors may be getting into the distributor and depositing on contact surfaces of points. This causes arcing and rapid burning of contact points. Oil vapor entering distributor usually produces a smudgy line on breaker plate under the points.

- High voltage, or any other condition in electrical system which causes excessive flow through contact points results in a blue scale forming on point surfaces. Check condenser circuit for high series resistance (par. 10-44). Check voltage and current regulator (par. 10-26).

- A radio capacitor connected to distributor terminal will cause excessive pitting of contact points. Capacitor should be connected to the positive (battery) terminal of coil.

Crank engine until breaker arm rubbing block is near top of a cam lobe, then use screwdriver to turn the cam to obtain maximum point opening, and check with the indicator.

- Check 1955 Buick ignition timing as described in paragraph 10-41.

1955 Buick Distributor Cap and Rotor

- Wipe out 1955 Buick distributor cap with a clean cloth and inspect it for chips, cracks, and carbonized paths which would allow high-tension leakage to ground. Such defects require replacement of cap. Clean any corrosion from surfaces of terminal segments inside the cap. DO NOT USE EMERY CLOTH OR SANDPAPER. If segments are deeply grooved the cap should be replaced.

- Pull cables from terminal sockets in distributor cap and coil and inspect sockets for corrosion. Clean corroded sockets, using a stiff wire brush. BLOW all dust out of sockets and inside of cap.

- Replace rotor if badly burned.

- Apply a few drops of oil to wick in top of distributor earn, then install rotor and cap.

1955 Buick Ignition Coil

Faulty 1955 Buick ignition coil operation can be caused by moisture, grease or dirt on the coil cap. Wipe off coil with clean cloth. Check the high tension cable connection to make sure it is clean and tight and that the cable nipple is properly placed over the secondary terminal. If coil is suspected of being faulty it should be tested with a reliable instrument (par. 10-43).

1955 Buick Spark Plugs and Wires

1955 Buick spark plugs and wires should be removed, cleaned and inspected as described in paragraph 10-42.

10-41 1955 BUICK IGNITION TIMING

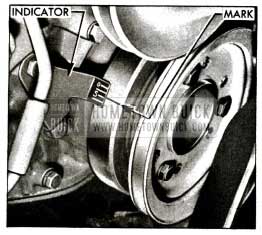

The timing mark is a groove filled with yellow paint, which is on the rear edge of the crankshaft pulley (Series 40) or the harmonic balancer (Series 50-60-70). A timing indicator, mounted on the timing chain cover, has four grooves filled with yellow paint. These grooves indicate U.D.C. (marked "0"), 2 1/2 degrees, 5 degrees (marked "5"), and 7 1/2 degrees before U.D.C. See figure 10-46.

1955 Buick Ignition Timing Mark and Indicator

Correct timing exists when the yellow timing mark on pulley or balancer is aligned with the 5 degree ("5") groove on the timing indicator at the instant that a spark occurs at No.1 spark plug. Firing then occurs 5 degrees before the piston reaches upper dead center.

1955 Buick Ignition timing should be checked with a power timing light, with the engine running. NOTE: Contact point opening must be within specified limits before setting ignition timing (par. 10-45, d).

- Connect a 12-volt power timing light to No. 1 spark plug wire at the distributor cap, using a suitable adapter and following the instructions of the instrument manufacturer. CAUTION: Do not attach timing light clip directly to spark plug boot as boot may be punctured so that arc over will occur.

- Start engine and set it to idle at a speed not to exceed 350 RPM, so that vacuum and centrifugal advance mechanisms are not in operation. This is absolutely necessary to insure correct timing.

- Direct the beam of timing light upon the timing indicator and rear edge of the pulley or balancer. The yellow timing mark must be aligned with the indicator line marked "5" for proper 1955 Buick ignition timing.

- If necessary, loosen the clamp bolt and turn the distributor housing very slowly in required direction to bring the yellow timing mark into alignment with the 5 degree line on indicator, then tighten clamp bolt securely.

- Reset engine idle speed to 450 RPM.

- Remove adapter or extra wires used with timing light, make certain that spark plug wires are securely pushed into distributor cap towers and that spark plug boots are properly installed.

10-42 1955 BUICK SPARK PLUG AND WIRE SERVICE

Remove and Inspect 1955 Buick Spark Plugs and Wires

- Remove spark plug covers, disconnect wires, then remove spark plugs and gaskets using a 13/16″ socket wrench. Use care in this operation to avoid cracking spark plug insulators.

- Carefully inspect the insulators and electrodes of all spark plugs. Replace any spark plug which has a cracked or broken insulator, or which has loose electrodes. If the insulator is worn away around the center electrode, or the electrodes are burned or worn so they cannot be adjusted for proper gap, a spark plug is worn out and should be discarded. Spark plugs which are in good condition except for carbon or oxide deposits should be thoroughly cleaned and adjusted.

- Wipe 1955 Buick ignition wires with cloth moistened with kerosene, and wipe dry. Bend wires to check for brittle, cracked, or loose insulation. Defective insulation will permit missing or cross-firing of engine, therefore defective wires should be replaced.

- If the wires are in good condition, clean any terminals that are corroded and replace any terminals that are broken or distorted. Replace any broken or deteriorated cable nipples or spark plug boots.

1955 Buick Spark Plug Cleaning

1955 Buick Spark plugs which have carbon or oxide deposits should be cleaned in a blast type spark plug cleaner. Scraping with a pointed tool will not properly remove the deposits and may damage the insulator. If spark plugs have a wet or oily deposit dip them in a degreasing solvent and then dry thoroughly with dry compressed air. Oily plugs will cause the cleaning compound to pack in the shell.

Carefully follow the instructions of the manufacturer of the cleaner being used, cleaning each plug until the interior of shell and the entire insulator are clean; however, avoid excessive blasting.

Examine interior of plug in good light. Remove any cleaning compound with compressed air. If traces of carbon or oxide remain in plug, finish the cleaning with a light blasting operation. Clean firing surfaces of center and side electrodes with several strokes of fine sandpaper.

When spark plugs have been thoroughly cleaned, carefully inspect for cracks or other defects which may not have been visible before cleaning.

Adjusting 1955 Buick Spark Plug Gap

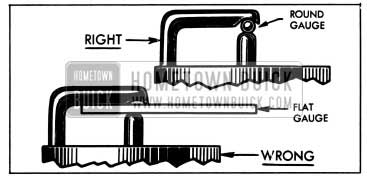

Use round wire feeler gauges to check the gap between spark plug electrodes. Flat feeler gauges will not give a correct measurement if the electrodes are worn. See figure 10-47.

1955 Buick Right and Wrong Spark Plug Gauges

Adjust gap by bending the side electrodes only; bending the center electrode will crack the insulator. Adjust gaps to .030″ Go and ,035″ No Go. Setting 1955 Buick spark plug gap to any other specification to improve idle or effect other changes in engine performance is not recommended.

Installation of 1955 Buick Spark Plugs

Use only AC type 44-5 spark plugs with 3/8″ long terminal nuts.

When installing spark plugs make sure that gaskets are in good condition to insure a tight seal and that surfaces on plug shells and seats in cylinder head are clean. Screw plugs down by hand into firm contact with gaskets, then tighten them to 22-28 ft. lbs. torque, using a 13/16″ socket, an extension, and a torque wrench. If a torque wrench is not used, do not tighten plugs excessively.

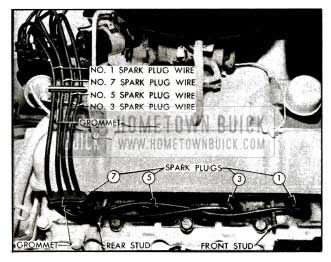

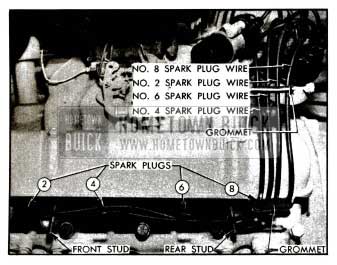

Installation of 1955 Buick Spark Plug Wires

Because No. 3 and No. 1 cylinders fire consecutively in the right bank and No. 8 and No. 4 cylinders fire consecutively in the left bank, spark plug wires for these cylinders must not be adjacent to each other in the grommets. The wires must be arranged as shown in figures 10-48 and 10-49 in order to avoid cross-firing and other adverse effects such as engine missing and short spark plug life. Where wires pass through rubber grommets at edge of spark plug covers they must be placed as indicated by cylinder numbers stamped on cover.

1955 Buick Spark Plug Wires-Right Bank

1955 Buick Spark Plug Wires-Left Bank

10-43 1955 BUICK IGNITION COIL TESTS

Weak Coils

Most ignition coils that are replaced by service stations are classified by them as weak. Many coils rejected as weak actually test up to specifications and give normal performance.

A coil that actually is weak will first affect engine performance when the ignition reserve is at a minimum. This may be in starting, low Speed acceleration or top speed. Eventually the engine will fail to start.

High resistance connections in either the primary or secondary circuit wiring will react the same as a weak coil. Wide spark plug gaps, which require higher voltage than the coil can produce, put the coil under suspicion. High compression and lean carburetors increase the voltage requirements and lead to many needless coil changes. Leakage of high tension current through moisture on an unprotected coil terminal may produce carbon tracks which weaken the coil output voltage. For this reason the nipple on coil high tension terminal must be properly installed and in good condition.

When a 1955 Buick ignition coil is suspected of being defective it should be tested as described below before being replaced.

Testing Coil for Open and Grounded Circuits

Before using a coil test instrument, the coil should be tested for open and grounded circuits, using a 110-volt test lamp and test points.

- Apply test points to both primary terminals of coil. If test lamp does not light, the primary circuit is open.

- Apply one test point to the high tension terminal, and the other test point to one of the primary terminals. If secondary circuit is not open, the lamp will not light but tiny sparks will appear at test points when they are rubbed over terminals. If secondary circuit is open, no sparks will occur.

- Apply one test point to a clean spot on the metal coil case and touch the other point to the primary and high tension terminals. If the lamp lights, or tiny sparks appear at the points of contact, the coil windings are grounded.

- A coil with open or grounded windings must be replaced since internal repairs cannot be made. It is unnecessary to test such a coil with instruments. If windings are not open or grounded, a test for short circuits and other internal defects should be made with a reliable coil test instrument.

Coil Test Instruments

Two general types of instruments are used in testing 1955 Buick ignition coils. One type makes use of an open or protected spark gap, while the other reports the condition of the coil on a meter.

The spark gap type of tester should always be used comparatively, that is, the questionable coil should be compared with a coil of same model that is known to be good. Both coils must be at the same temperature and identical test leads must be used. Certain variables caused by altitude, atmospheric or spark gap electrode conditions are usually present in the spark gap type of test.

The meter type testers are usually designed to permit testing the coil without making any connection to the secondary terminal. This eliminates the variables usually present in the spark type of test and avoids the necessity for comparison with a good coil.

Since different makes and models of coil testers differ in their methods of use, as well as in the markings on meters, the instructions of the manufacturer must be carefully followed when using any coil tester. The instrument must be frequently checked to make certain that it is accurately calibrated.

Regardless of instrument or method used, the coil must be tested at normal operating temperature because internal defects often fail to show up on a cold test.

10-44 1955 BUICK DISTRIBUTOR CONDENSER TESTS

When a condenser is suspected of being faulty it should be tested with a reliable condenser tester to determine whether it is actually the cause of ignition trouble. The condenser should be tested for (a) high series resistance (b) insufficient or excessive capacity (c) low insulation resistance.

A special condenser tester is required to make these tests. When using a condenser tester the instructions of the manufacturer must be carefully followed. IMPORTANT: The condenser must be at normal operating temperature when it is being tested.

High Series Resistance

High series resistance in the condenser circuit causes condenser to be slow in taking the charge and, consequently, a higher than normal voltage is developed across the contact points when they first start to open. This higher voltage causes more disturbance at the contact points, which in turn causes more rapid wear and more tendency toward oxidized surfaces. The condition can become severe enough to cause complete failure of the 1955 Buick ignition system. It would first show up during starting and low Speed operation.

High series resistance may be caused by internal resistance in condenser or by resistance in the connections. Any defect caused by internal resistance should show up at low mileage since this does not change very much with time or use. The damaging changes are in the connections, in which looseness, corrosion, or broken strands may develop.

New condensers may have a series resistance as low as .05 ohm. Some condenser testers are set to reject condensers which have a resistance of .3 ohm; however, tests show that the resistance can go to .5 ohm before ignition performance is affected.

Insufficient or Excessive Capacity

The condenser specified for use in the 1955 Buick ignition system has a capacity of .18 to .23 microfarads.

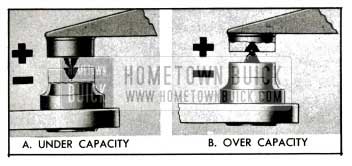

If a condenser is used which does not have the specified capacity of .18 to .23 microfarads, excessive pitting of one contact point and a corresponding build-up of metal on the other contact point will result. A condenser having insufficient capacity will cause build-up of metal on the breaker arm (positive) point. See figure 10-50, view A. A condenser having excessive capacity will cause build-up of metal on the contact support (negative) point. See figure 10-50, view B.

1955 Buick Result of Under or Over Capacity Condenser

In exceptional cases, pitting and metal build up on contact points may be experienced even when condenser capacity is within the specified limits. In such cases the life of contact points will be improved by installing a condenser of high-limit capacity if metal build-up is on breaker arm point, or a condenser of low-limit capacity if metal build-up is on contact support point. There is usually sufficient variation in the capacities of stock condensers to permit selection of a high or low limit condenser by testing the available stock.

Low Insulation Resistance

A weak or leaking condenser is usually one that has absorbed water so that the insulation resistance of the winding is lowered to the extent that the condenser will not hold a charge satisfactorily. A condenser with low insulation resistance will drain sufficient energy from the 1955 Buick ignition system to lower the secondary voltage seriously. The condenser specified for use in the 1955 Buick ignition system is sealed to prevent absorption of water, and no other type should be used.

A leaky condenser usually does not affect engine performance except when hot. It is unlikely that a condenser with low insulation resistance would cause missing at low or medium speeds under conditions where the condenser does not get hot. A condenser that has low enough resistance to affect engine performance when cold would probably be indicated as broken down on most condenser testers.

Condenser testers equipped to check condensers for low insulation resistance usually give a reading in megohms, a megohm being one million ohms. The scale is marked to indicate whether the condenser is good or bad.

When testing a condenser for low insulation resistance the lead should always be disconnected from the distributor. Since the distributor terminals and the connected circuit have much lower insulation resistance than the condenser, failure to disconnect the condenser lead will give a reading much too low.

10-45 1955 BUICK DISTRIBUTOR SERVICE OPERATIONS

Removal and Disassembly of 1955 Buick Distributor

- Disconnect primary wire from 1955 Buick distributor and disconnect pipe from vacuum control unit. Remove distributor cap.

- Crank engine until 1955 Buick distributor rotor is in position to fire No. 1 cylinder, and the yellow timing mark on crankshaft pulley or balancer is approximately aligned with the 5 degree mark on timing indicator. See figure 10-46.

- Remove distributor clamp and lift distributor out of crankcase.

- Remove rotor and breaker plate ground lead, then remove the vacuum control and gasket. See figure 10-51.

1955 Buick Distributor Parts

Inspect and Replace Parts in Housing

- Wash the cam and the housing assembly in clean solvent, holding housing horizontal to avoid getting cleaning solvent into the lubricant reservoir. Dry parts thoroughly.

- Inspect 1955 Buick distributor cam and replace it if the lobes are scored or excessively worn.

- Inspect shaft for excessive looseness in bushings in distributor housing. Inspect distributor gear for wear or scoring of teeth. Check end play of shaft with feeler gauges; end play should not exceed .007″.

- If parts in housing require replacement, remove flathead screw and spring from housing to relieve pressure on the felt plug which bears against distributor shaft.

- Grind or file off the peened-over head of gear pin and drive pin out.

- Remove gear, shim washer and thrust washer from shaft, then remove shaft and plate assembly and thrust washer from housing.

- When shaft and plate assembly is installed in housing place one thrust washer between weight plate and housing. A shaft shim washer of proper thickness must be placed between the lower thrust washer and gear to provide .002″ to .007″ end play in shaft when gear is installed. Shim washers are furnished in .005″ and .010″ thicknesses.

- Peen over the head of gear pin after installation of shaft is completed, then recheck end play.

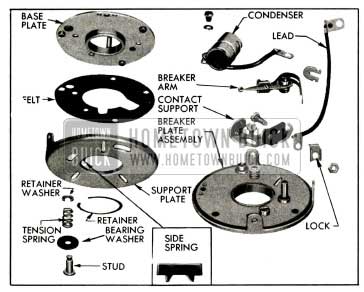

Inspect and Replace Parts on Breaker Plate

- Inspect ground and terminal connector leads and replace if oil soaked, have broken strands, or terminals are loose.

- Test the condenser if a reliable condenser tester is available (par. 10-44).

- Inspect contact points for excessive wear, pitting or burning. Inspect breaker arm spring for cracks and rubbing block for wear or looseness. Remove parts from breaker plate if replacement is required.

- Inspect breaker plate assembly for looseness which would permit excessive tipping or rattling of base plate. Normally it is unnecessary to disassemble this unit; however, if it is very dirty disassemble for cleaning and inspection as follows:

- Remove tension spring retainer washer from stud, then remove spring, stud, and bearing washer. See figure 10-52.

1955 Buick Breaker Plate Parts

- Saturate lubricating felt with low engine oil, then install base plate on support plate.

- Place the small side pressure spring in recess in support plate so that the two points will be between the ends of the retainer when installed. The spring helps to prevent side play of base plate. See figure 10-52.

- Install one retainer in groove in base plate hub; the hub is staked at four places to provide end play of approximately .015″ between base plate and support plate.

- Install stud with bearing washer against support plate, then install tension spring and retainer washer on upper end of stud.

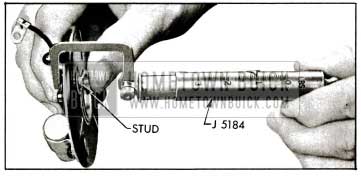

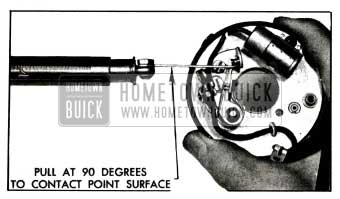

- Apply hook of Scale J 5184 to upper end of tension spring stud, above the retainer washer, and while holding scale in horizontal position check the pull required to just start movement of the stud. See figure 10-53. Pull should be 18 to 24 ounces; if it is not, carefully stretch tension spring or replace it to obtain pull within specified limits.

1955 Buick Checking Strength of Tension Spring

1955 Buick Checking Friction Between Plates

Pull required to rotate base plate should not exceed 15 ounces; if it does, check for dirt between plates, insufficient lubrication, or distorted plates, and make correction to bring pull within maximum of 15 ounces.

1955 Buick Parts Installed on Breaker Plate

Leave screw just loose enough so that the screw can be shifted in the slotted insulating block.

1955 Buick Checking Breaker Arm Spring Tension

Tension must be 19 to 23 ounces.

Breaker arm spring tension is very important. Weak tension will cause breaker arm to flutter and bounce at high speed resulting in engine missing. Excessive spring tension will cause rapid wear of breaker arm rubbing block and cam, resulting in insufficient contact point opening. Excessive spring tension can cause tilting of the breaker base plate, which would affect contact point opening.

Assembly and Adjustment of 1955 Buick Distributor

- Place advance weights over pins on shaft weight plate. Install cam over shaft with advance cam between the weights and with the stop pin in hole in weight plate.

- Place hold down plate over weights with ridged side down against weights. Install locks and nuts and bend tongue of locks up against nuts. Install advance weight springs on pins. See figure 10-57.

1955 Buick lnstallation of Advance Weights, Cam, Springs and Plate

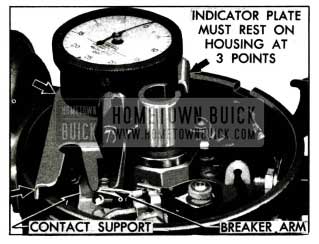

1955 Buick lndicator for Checking Contact Point Opening

Installation of 1955 Buick Distributor

NOTE: Before installation of either a new or repaired 1955 Buick distributor apply a few drops of engine oil to drain hole near lower end of housing and apply oil to oiler on housing. Rotate shaft several times by hand to distribute lubricant and to make sure that shaft turns freely.

- Check to make sure that timing mark on crankshaft pulley or balancer is aligned with the 5 degree mark on timing indicator, with No. 1 piston on compression stroke.

- Place a new O-ring oil seal on distributor housing.

- Rotate distributor cam in direction of arrow on cam until rotor is in position to fire No.1 cylinder.

- Rotate oil pump shaft with screwdriver to align slot in shaft with tongue on lower end of distributor shaft. Install distributor in crankcase with vacuum control pointing to right side of engine in position to connect to the vacuum pipe.

- Install distributor clamp and bolt with lock washer, leaving bolt just loose enough to permit movement of distributor. Rotate distributor housing counterclockwise until contact points just start to open, then tighten clamp bolt. This will permit starting engine for setting the timing.

- Connect pipe to vacuum control and connect primary wire to terminal stud.

- Install 1955 Buick distributor cap. If 1955 Buick spark plug wires are disconnected from cap make certain that wires are connected in accordance with the firing order, 1-2-7-8-4-5-6-3.

- If spark plug wires were removed from plugs, make certain that they are arranged as shown in figures 10-48 and 10-49. Wires must be pushed all the way down into distributor cap terminals and the nipples must be pushed firmly over the terminals.

- Check and set ignition timing as described in paragraph 10-41.

10-46 1955 BUICK IGNITION SWITCH AND LOCK REPAIRS

1955 Buick Ignition Switch Key

If 1955 Buick ignition key sticks or feels rough as it is inserted into the lock, examine it for burrs and smooth up with a fine cut file. BLOW finely powdered graphite into lock cylinder, then work key in and out of cylinder a number of times to work graphite into tumblers. Do not use oil in lock cylinder as this will cause tumblers to stick.

If ignition switch key is lost and key code number is not known, the code number will be found stamped on the door safety lock, which must be removed. A new key can be cut by using this code number.

Lock Cylinder Replacement

To remove 1955 Buick lock cylinder, insert key and turn 1955 Buick ignition switch to "OFF" position. Insert a stiff wire (paper clip) in small hole in face of cylinder to depress the pin which locks the cylinder, turn cylinder clockwise and pull out. To install lock cylinder insert key, place cylinder in switch slightly clockwise from "OFF" position, press inward and turn cylinder counterclockwise.

1955 Buick Ignition Switch Replacement

- Disconnect battery cable from junction block to avoid a possible short circuit when disconnecting wires from switch terminals.

- Remove lock cylinder (subpar. b, above).

- Remove shield which is attached to steering column support.

- Remove switch attaching screws, remove switch from forward side of instrument panel, and disconnect wires from switch terminals.

- When switch is installed be careful to connect wires to terminals as shown in the chassis wiring circuit diagrams in Section 10-J. Be sure to install switch terminal shield with new "theft proof" screws. Connect battery ground cable in proper manner to make an initial winding of clock and set clock. See paragraph 10-56.

Removal of Lock Cylinder Which Cannot be Unlocked with Key

When 1955 Buick ignition switch fails to unlock with the proper key, and lock has previously been operating satisfactorily, the lock cylinder can be removed as follows:

- Draw a centerline on cylinder at 90° to key slot, insert key, and make a prick punch mark on centerline 3/8″ from side of key. Carefully drill a .0465 hole (No. 56 drill) through cylinder flange at this point.

- File the end of a stiff wire (paper clip) to a taper. Insert this end of wire in drilled hole to pry the cage bar assembly down so that lock cylinder can be turned. After turning cylinder slightly, remove the wire to avoid wedging, then remove lock cylinder in the regular manner (subpar. b, above).

- Stake cage bar in place at four points. Staking must not distort cage. Reinstall lock cylinder and check operation with key. If operation is satisfactory, plug the drilled hole with a small pin No. 00 x 1/8″ (Parker Kalon type "U").

Share This Story, Choose Your Platform!

Source: https://www.hometownbuick.com/1955-buick-ignition-system/

Posted by: gototerryees.blogspot.com

Posting Komentar untuk "03 Buick Ignition Switch Diagram"